Our Production Capabilities

Turret Punch Presses

Key Features of Cobra Kustom Fab’s CNC Punching and Turret Equipment

At Cobra Kustom Fab, we harness cutting-edge CNC punching and turret equipment to deliver precision and performance on every project. Our shop is equipped with top-tier machinery from industry leaders like Amada, ensuring unmatched accuracy, versatility, and efficiency for all our custom fabrication needs.

Press Brakes

Precision Formed. Built the Cobra Way.

At Cobra Kustom Fab, we take on everything from sharp 90° bends to complex cones, transitions, and full assemblies with precision and power. Our press brakes are dialed in to meet exact customer specs — whether it’s a one-off custom job or full-scale production. We make assembly faster and more efficient for every client. From carbon steel and stainless to aluminum, brass, copper, and more, our machines turn raw material into high-quality parts built to laser-weld tolerances.

Welding

Cobra Kustom Fab Welding Services

Cobra Kustom Fab delivers precision MIG and spot welding built for strength and consistency. Our skilled welders join carbon steel, stainless steel, aluminum, and galvanized materials with clean, durable welds that last. When you need parts fused tough and finished right, Cobra Kustom Fab gets it done.

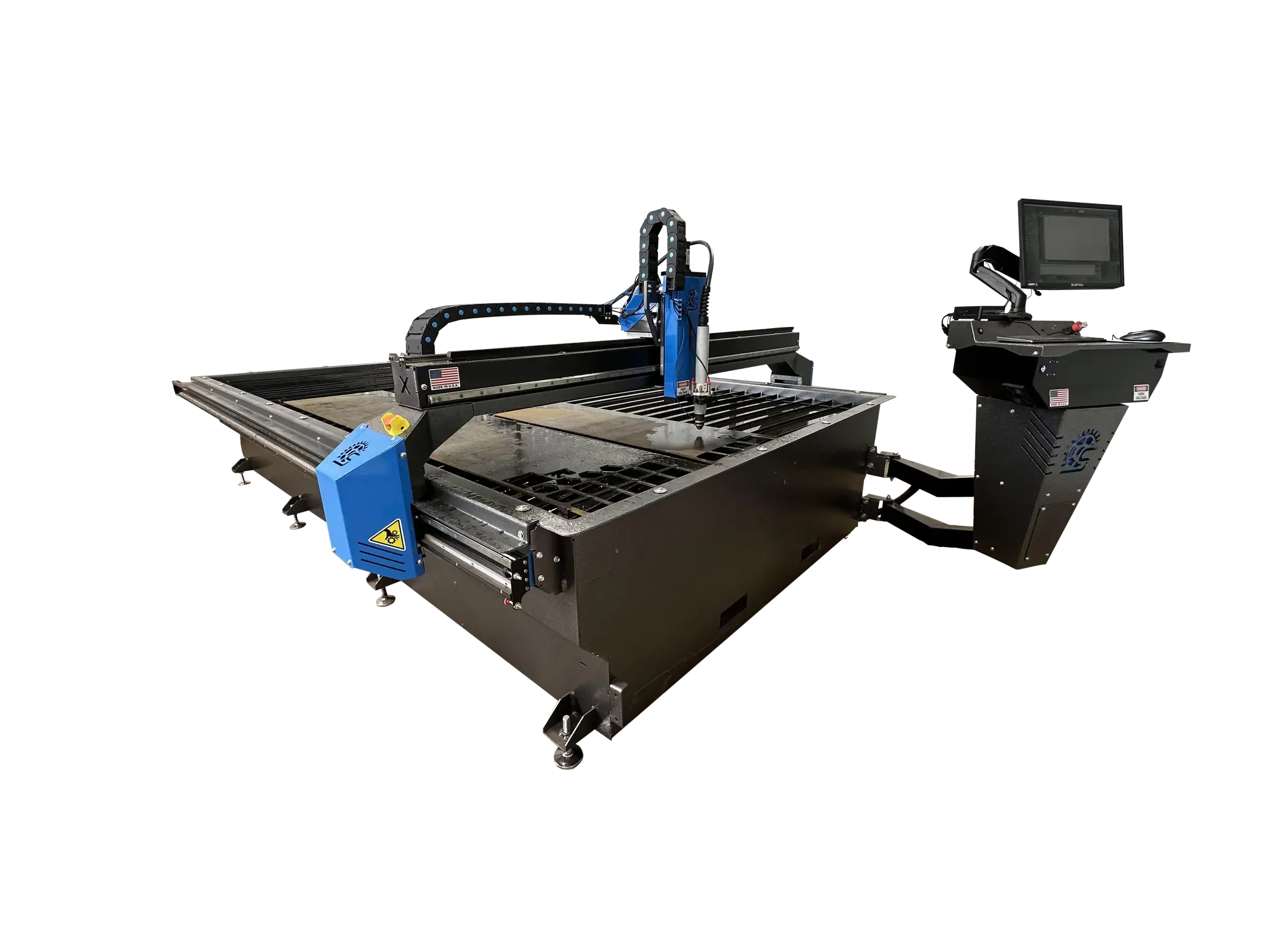

Plasma Cutting

Advantages of Plasma Cutting Services

Cobra Kustom Fab’s plasma cutting services deliver unmatched precision and accuracy. Our plasma table excels at handling a wide range of metals, fabricating complex shapes with exceptional detail and consistency. The speed and efficiency of plasma cutting enable faster turnaround times and lower operational costs, making it a critical tool for projects that demand high-quality, rugged, and cost-effective manufacturing solutions.

Custom, Prototype & Production

Sheet Metal Fabrication

At Cobra Kustom Fab, we specialize in custom, prototype, and production sheet metal fabrication built for precision and performance. From one-off designs to full-scale production runs, our team delivers high-quality results with tight tolerances and dependable consistency. Equipped with advanced machinery and expert fabricators, Cobra Kustom Fab turns raw sheet metal into tough, accurate, and ready-to-install components — built to your exact specs.